Description

ASTM D6648 • EM 14771 • AASHTO T313 • AASHTO TP 87

| Load Gövde | Integral stainless steel frictionless construction |

| Loading Shaft | In-line stainless steel with blunt point |

| Test Load | Variable test range from 0 to 400 mN Standart. System maintains required test load within +/- 5mN throughout test cycle. |

| Test Cycle Times | Cycle times for pre-load, recovery, and test load are completely operator-adjustable |

| Load Cell | 500g (temperature-compensated) |

| Mechanical Overload Protection | Standard |

| Test Weights | Calibrated and traceable to NIST |

| Sample Supports | 3mm (.118”) radius stainless steel spaced 4.00in (101.6mm) apart |

| LVDT Displacement Transducer | 0.25 in. (6.35mm) calibrated range to provide 2um resolution throughout testing and verification range |

| Data Display | Large on-screen display of load, displaÇİMENTO, and bath temperature provides ease of setup and operation. Realtime displaÇİMENTO, loading, and temperature graphs are displayed during the test cycle and can be re-plotted and re-scaled as needed for easy viewing. |

| Cooling Unit | Included (non-CFC refrigerant) |

| Recommended Cooling Bath Fluid | Non-flammable ethylene glycol mixture |

| Operating Temperature | Ambient to -40°F (-40°C) |

| Temperature Measurement | Platinum RTD |

| Power Requirements | 115VAC 50/60Hz Standard 230VAC 50Hz Optional |

| Compressed Air Requirements | 50 psi (0.34 MPa) clean, dry air supply required |

| Dijital Air Regulation | Linearity of < +/- 1.5% of span Hysteresis Repeatability < 1.0% of span Supply Pressure Sensitivity < 0.2% of span per 1.0 PSIG |

- Used to perform flexural tests

- on asphalt binder and similar specimens as part of the PG grading system according to Superpave.

- Its new external chiller is now more compact and omits less noise during operation. Programmable test parameters allow users to input and save their own unique settings, allowing the Bending Beam Rheometer to satisfy a diverse range of testing applications.

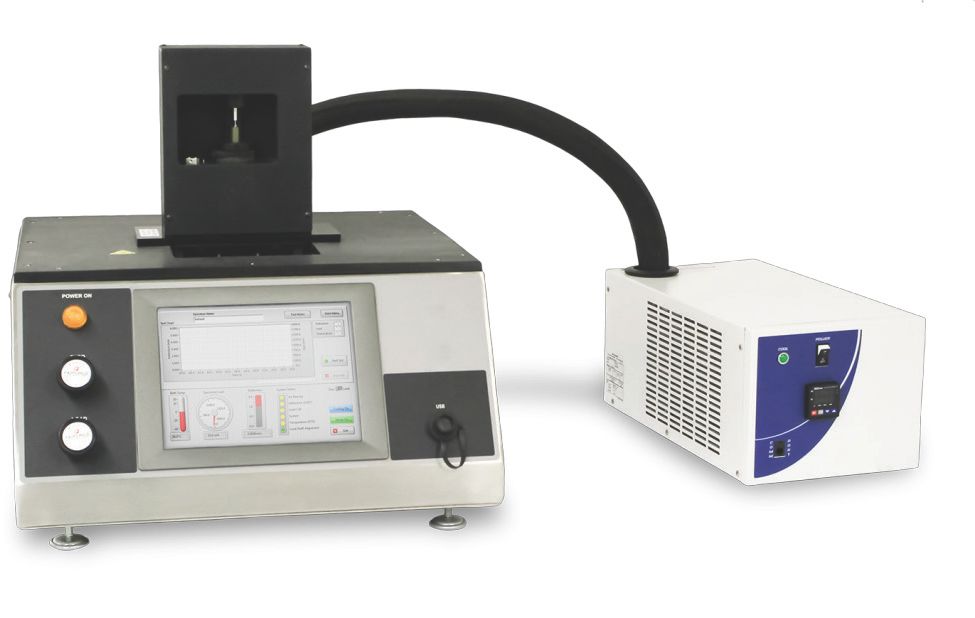

- Consists of a fluid bath base with a built-in touchscreen computer, load Gövde, and external chiller.

- During operation, a known force is applied to the center of a horizontally supported specimen beam submerged in a cold liquid bath while internal software calculates the flexural creep stiffness of the beam.

- Used in part to determine a sample’s critical cracking temperature and low temperature PG grade, the Bending Beam Rheometer’s -40°C to 25°C temperature range is efficiently calculated by a platinum RTD measuring device.

- The 500g load cell and changeable specimen supports easily transition the Bending Beam Rheometer for crack sealant testing, and the free standing external chiller ensures that the cooling fluid maintains a constant temperature.